| Materials: |

- Steel (Carbon Steel, Alloy Steel)

- Stainless Steel (Austenitic, Martensitic, Ferritic)

- Aluminum Alloys

- Brass and Bronze Alloys

- Copper Alloys (including Beryllium Copper)

- Titanium and Titanium Alloys

- Plastics (Nylon, PTFE, PVC)

|

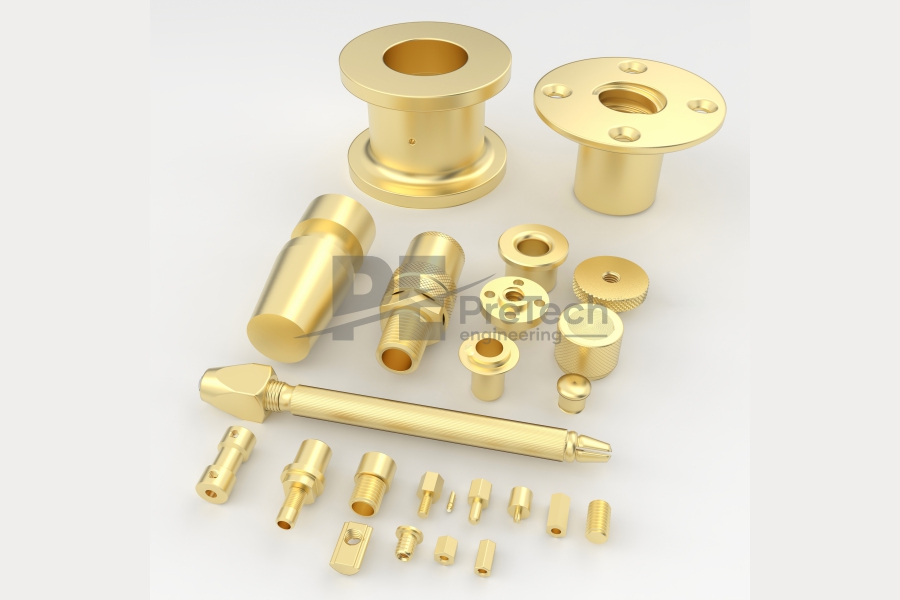

| Types: |

- Turned Shafts and Axles

- Turned Pins and Fasteners

- Turned Bushings and Bearings

- Turned Couplings and Connectors

- Turned Valves and Fittings

- Turned Rods and Bars

- Custom Turned Components as per Drawings and Specifications

|

| Advantages: |

- Precision Machining with Tight Tolerances

- High Surface Finish and Accuracy

- Customizable Designs and Configurations

- Cost-Effective Production for Large Quantities

- Reduced Material Wastage

- Quick Turnaround Time for Prototypes and Production Runs

- Wide Range of Machinable Materials

- Enhanced Mechanical Properties (Strength, Durability)

- Compatible with CNC Turning and Milling Processes

|

| Applications: |

- Automotive Industry (Engine Components, Transmission Parts)

- Medical Equipment (Surgical Instruments, Implants)

- Aerospace and Defense (Aircraft Components, Missile Parts)

- Electrical and Electronics (Connectors, Terminals)

- Hydraulic and Pneumatic Systems (Fittings, Adapters)

- Industrial Machinery (Pumps, Valves, Gears)

- Consumer Goods (Home Appliances, Sporting Equipment)

- Oil & Gas Sector (Drilling Tools, Pump Components)

- Marine Applications (Ship Components, Propeller Shafts)

|